The Role of Industrial Blade Manufacturers in Modern Industry

Your choice of blades can make a significant difference in the efficiency and effectiveness of your operations. Industrial blade manufacturers like SZBlade provide a vast array of cutting tools designed for various applications, ensuring that businesses can meet their specific needs with precision and reliability.

Understanding Industrial Blades and Their Applications

Industrial blades are specialized cutting tools that are utilized in various industries, from manufacturing to agriculture. These blades are engineered from high-quality materials and designed to endure harsh environments and heavy usage. Some common applications include:

- Manufacturing: Used in machining and assembly lines for precise cuts.

- Pulp and Paper: Essential for cutting raw materials and finished products.

- Agriculture: Employed in harvesting and processing crops.

- Food Processing: Used for slicing, dicing, and chopping food products.

Why Partnering with Quality Industrial Blade Manufacturers Matters

Choosing to work with reputable industrial blade manufacturers like SZBlade offers several advantages:

- Quality Assurance: Manufacturers such as SZBlade use advanced technologies and quality control measures to ensure that their products meet high standards.

- Durability: Quality blades are built to last, reducing the frequency of replacements and consequently, costs.

- Customization: Reputable manufacturers provide options for custom blades tailored to specific applications and requirements.

- Expert Support: Leading manufacturers offer professional support, including knife sharpening services, enhancing blade performance.

A Closer Look at SZBlade: A Leading Industrial Blade Manufacturer

At SZBlade, we pride ourselves as one of the foremost industrial blade manufacturers in the industry. Our commitment to quality and innovation ensures that our clients receive the best possible products and services. Some of our key offerings include:

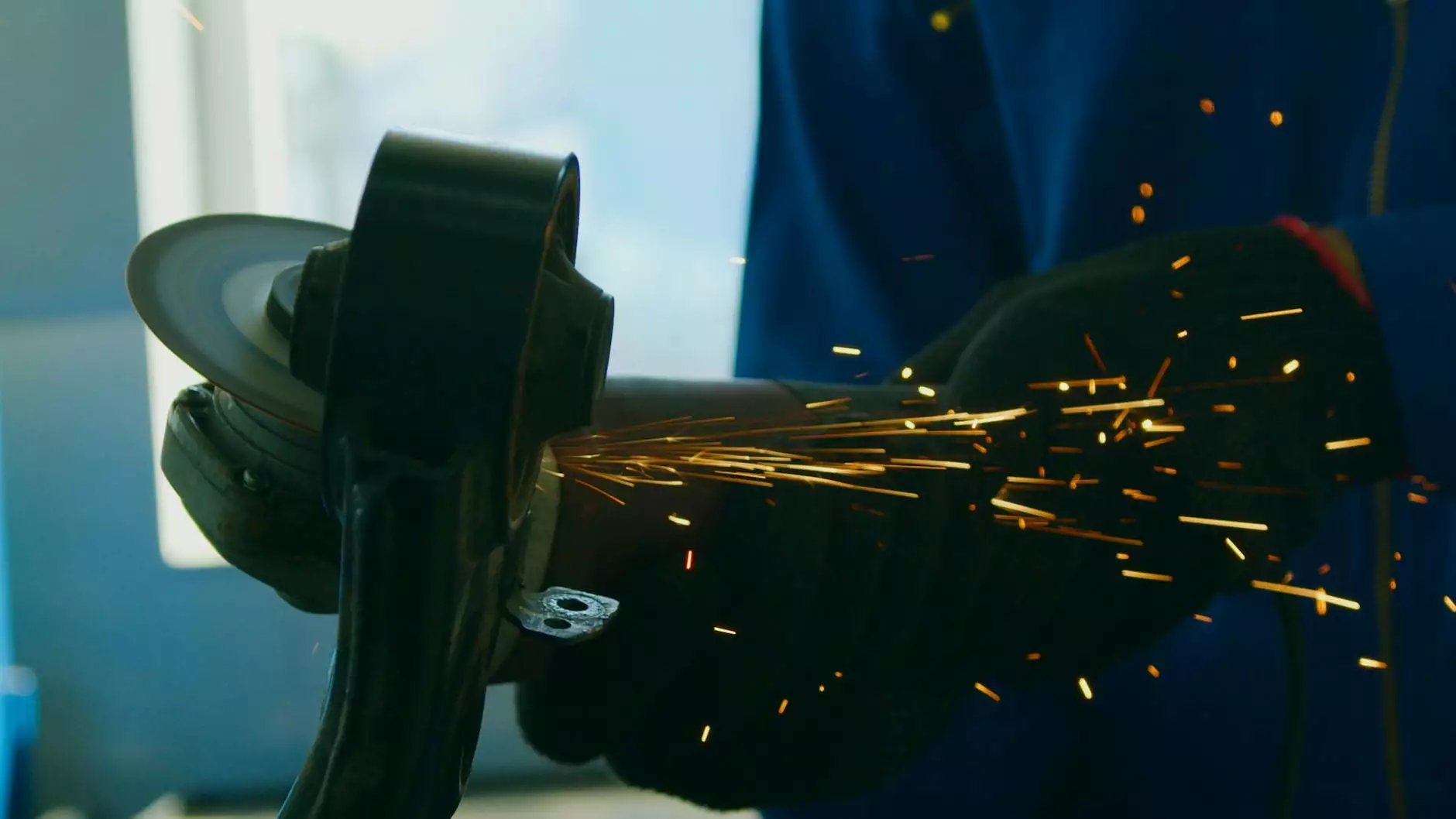

High-Performance Blades

Our blades are designed to deliver superior cutting capabilities. We utilize the latest technology and materials to manufacture blades that can withstand rigorous use. Our products are suitable for:

- Cutting metal and wood with precision.

- Handling complex cutting patterns in various industrial processes.

- Providing optimal performance in food processing environments.

Professional Knife Sharpening Services

In addition to providing high-quality blades, we also offer professional knife sharpening services. Regular sharpening is essential to maintain blade efficiency and prolong lifespan. Our sharpening services include:

- Precision sharpening: Utilizing advanced techniques to ensure a sharp edge.

- Restoration services: Bringing old, worn blades back to life.

- Consultation: Offering advice on blade maintenance and the best sharpening practices.

The Importance of Advanced Materials in Blade Manufacturing

The performance of blades heavily relies on the materials used in their composition. At SZBlade, we focus on utilizing:

- High Carbon Steel: Known for its hardness and resistance to wear, ideal for heavy-duty applications.

- Stainless Steel: Provides excellent corrosion resistance, essential for the food industry.

- Tungsten Carbide: Used in blades that require exceptional durability and performance in abrasive conditions.

Innovative Technologies in Blade Manufacturing

The continuous evolution of technology affects every sector, including blade manufacturing. Innovations in this field are aimed at enhancing performance and user experience:

- Laser Cutting: Provides precision blades by ensuring exact measurements and cuts.

- CNC Machining: Enhances manufacturing efficiency while maintaining high tolerances.

- Coating Technologies: Introducing specialized coatings that improve durability and reduce friction.

Environmental Responsibility in Blade Manufacturing

As an exemplary industrial blade manufacturer, SZBlade takes environmental responsibility seriously. Our practices include:

- Sustainable Materials: Sourcing materials that have minimal environmental impact.

- Waste Recycling: Implementing processes to recycle scrap materials during production.

- Energy Efficiency: Utilizing machines and processes that reduce energy consumption.

How to Choose the Right Industrial Blade Manufacturer

Selecting the right manufacturer involves considering several critical factors:

- Reputation: Look for manufacturers with a proven track record and positive customer reviews.

- Product Range: A diverse product range indicates capability to serve various needs.

- Customer Support: Reliable after-sales support can enhance the overall customer experience.

- Certifications: Ensure that the manufacturer adheres to industry standards and has relevant certifications.

The Future of Industrial Blades: What to Expect

As industries evolve, so do the demands for cutting tools. Future trends in industrial blades may include:

- Smart Blades: Incorporating sensors to monitor blade health and performance.

- 3D Printing: Allowing for rapid prototyping and custom blade designs.

- Enhanced Materials: Development of new materials that offer improved performance and sustainability.

Conclusion: The Impact of Quality Blades on Industry Success

The significance of partnering with reputable industrial blade manufacturers cannot be overstated. With companies like SZBlade, businesses gain access to high-quality products, expert services, and the reassurance that they are investing in tools that will drive efficiency and productivity. As industries continue to evolve, the need for durable, innovative, and environmentally responsible blades will play a crucial role in shaping the future of manufacturing.

Contact Us for Your Industrial Blade Needs

If you are looking for premium industrial blades or knife sharpening services, reach out to SZBlade. We are committed to providing the best solutions tailored for your business needs. Let us partner with you for quality and precision in every cut.